If you’re a construction manager in the Philippines, you’re probably all too familiar with how bent rebar can throw a wrench in your projects. It not only eats into your budget with the need for new materials but also racks up extra costs for manual labor. But what if I told you that a rebar straightening machine for sale could turn things around? Let’s dive into how Marco, a construction manager in the Philippines, transformed his project using YG Machinery’s innovative solution.

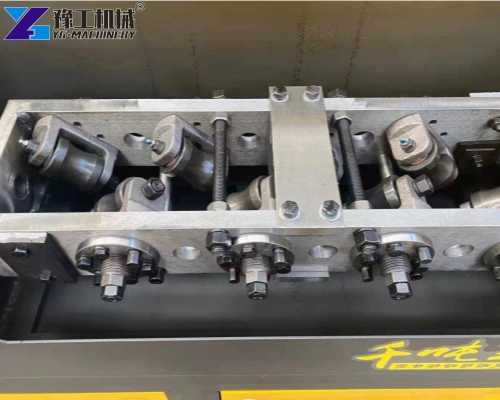

Parameters of Rebar Straightening Machine for Sale

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire Length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

Customer Profile: Marco’s Big Problem with Bent Rebar

Marco runs a mid-sized construction company in Cebu. His team works on residential buildings and small infrastructure projects. For years, they faced two big issues:

- They had tons of scrap bent rebar from old sites. Throwing it away wasted money.

- Manual straightening took 3 workers a full day to handle 1 ton of rebar. It was slow and imprecise.

- Buying new rebar every month costs them an extra ₱150,000. Marco needed a cheaper, faster way. That’s when he looked for a rebar straightening machine for sale.

Project Background: The Cebu Residential Project Push

Marco’s team won a contract to build 10 townhouses in Mandaue City. The project had a tight 8-month deadline. But there was a problem:

- The site had over 8 tons of scrap bent rebar. Using it would save money, but manual work would delay the project.

- The project needed straight rebar of 8mm to 14mm—exactly the size most rebar straightening machine for sale handle. Marco knew he couldn’t miss the deadline. He started searching online for a reliable rebar straightening machine for sale that could process scrap rebar quickly.

Why Marco Chose YG Machinery’s Rebar Straightening Machine for Sale

Marco compared 5 suppliers, but YG Machinery stood out. Here’s why:

Customized Solution for Philippine Needs

Marco needed a machine that could handle the hot, humid Cebu weather. YG’s team recommended the YGT 4-14 model—a rebar straightening and cutting machine that works in high humidity. It also adjusts to 4-14mm rebar, perfect for his project.

Clear Bar Straightening Machine Price

Marco couldn’t stand hidden costs. When YG provided him with a clear quote, he was pleasantly surprised to find it was 20% cheaper than what other suppliers offered. He felt confident that the price for the bar straightening machine was well within his budget.

Fast Pre-Sale Support

Marco had questions about setup. YG’s team sent a video guide in 24 hours. They also offered a virtual demo to show how the machine works. This made him confident to buy.

How the Rebar Straightening Machine Solved Marco’s Problems

Marco’s team received the rebar straightening machine for sale in 2 weeks. Here’s how it changed their work:

Speed That Beat the Deadline

The machine processes 50 meters of rebar per minute—10x faster than manual work. Marco’s team went from 1 ton per day to 5 tons per day. They finished the townhouse project 2 weeks early.

Scrap Rebar Turned to Savings

The machine turned 8 tons of scrap rebar into usable material. Marco didn’t buy new rebar for 3 months, saving ₱450,000. He even started using a rebar coil straightening machine (from YG too) to handle coiled rebar for future projects.

Precision That Avoided Mistakes

Manual straightening often left rebar uneven, leading to concrete cracks. YG’s machine has a straightening error of ±0.5cm, so every bar met Philippine construction standards. No more redoing work!

YG’s Post-Sale Support: No More Downtime Worries

3 months later, Marco’s machine needed a new roller. He contacted YG’s support team. Here’s what happened:

- YG sent the replacement part to Cebu in 10 days—free of charge.

- They offered a 30-minute video call to show his team how to install it.

- The machine came with a 1-year warranty, so Marco didn’t pay extra. Marco said: “The rebar straightening machine for sale was great, but the support made me a loyal customer. We haven’t had a single day of downtime.”

YG’s Global Reach: Trusted in 20+ Countries

Marco wasn’t the only one who benefited. YG’s rebar straightening machine for sale is used in:

- Mexico: A subway project used it to recycle 5 tons of rebar daily.

- UAE: A construction firm cut waste from 7% to 2%.

- Thailand: A precast factory uses the rebar straightening and cutting machine to make concrete piles. In the Philippines, YG has sold over 50 machines to firms in Manila, Cebu, and Davao. Why? Because the machines are durable, affordable, and fit local project needs.

Ready to Save Money Like Marco? Get Your Rebar Straightening Machine for Sale

If you’re tired of wasting money on new rebar and slow manual work, YG’s rebar straightening machine is the solution. Here’s what you get:

- A machine that handles 4-16mm rebar (perfect for Philippine projects).

- Transparent bar straightening machine price with no hidden fees.

- Free shipping, 1-year warranty, and 24/7 support.

Contact YG Machinery today to get a customized quote for your project. Let’s turn your scrap rebar into savings—just like Marco did!