A rebar coil straightening machine is a must-have for any high-efficiency construction project these days. It takes coiled reinforcing steel and transforms it into straight, ready-to-use bars in no time, with impressive accuracy. This one piece of equipment can significantly boost productivity on site. In fact, studies indicate that using automated straightening can ramp up output by as much as 40% compared to doing it manually. So, picking the right machine is a crucial decision for any construction company.

Parameters of Rebar Coil Straightening Machine

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire Length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

Why Straightening Precision Matters

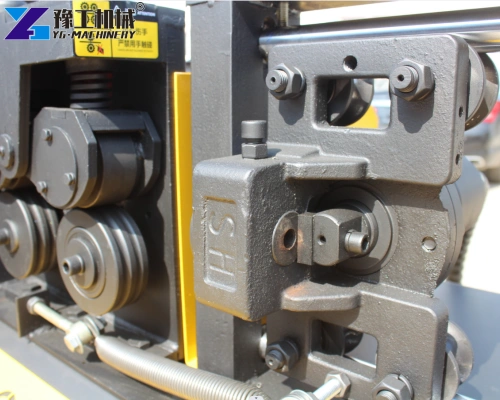

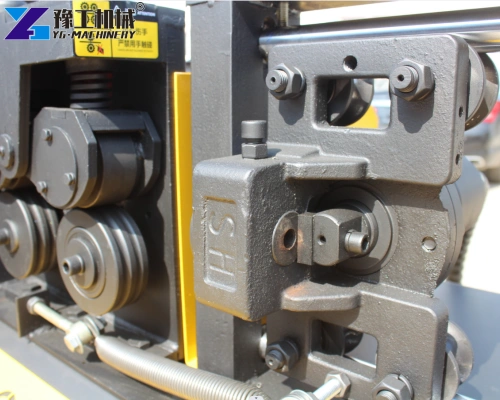

When it comes to choosing a rebar coil straightening machine, precision is absolutely key. The top machines are designed to maintain a very tight straightening tolerance, often within ±2 mm over a 10-meter bar. This level of accuracy not only reduces material waste but also ensures the structural integrity of your projects. A high-quality machine achieves this through a strong, specialised roller and rotary system. Plus, the best machines can handle High Tensile Steel Straightening, effectively working with materials up to Grade 500 or Grade 600 while delivering consistent results.

Smart Operations: The Power of PLC Automatic Control

Modern rebar coil straightening machines are equipped with cutting-edge PLC systems. This automatic control feature makes the operation straightforward, accurate, and easy to use. Operators can simply enter the length and quantity on a touch screen interface, and the machine takes care of the straightening and cutting all on its own. This level of automation not only cuts down on labour costs but also significantly reduces the chances of human error. Plus, it guarantees consistent quality across every batch of material.

Maximising Rebar Processing Productivity: Speed and Coil Feed System Integration

When it comes to high-volume projects, you need machines that really excel in Rebar Processing Productivity. The speed of these machines is usually measured in meters per minute. Top models can reach impressive speeds of up to 130m/min while handling standard HRB 400 rebar. But it doesn’t stop there—efficiency gets a boost from a dependable coil feed system. This system guarantees a smooth, uninterrupted flow of material, free from tangles or delays. It’s this seamless combination of feeding and processing that sets high-performing machines apart from the basic ones, especially when it comes to rebar straightening and cutting.

Cost-Effectiveness: Understanding Total Ownership and Rebar Straightening Machine for Sale

When searching for a rebar straightening machine for sale, focus on the long-term total cost of ownership (TCO). The initial purchase price is only part of the equation. Low-quality machines often have higher energy consumption, sometimes costing an extra 1,000$ annually in electricity. High-efficiency YG Machinery models feature energy-saving motors, minimising operational expenses. Moreover, check the warranty and the local availability of spare parts. This protects your investment and minimises costly downtime.

Practical Tip: Request specific data on power consumption (kW) per ton of processed steel.

Expanding Applications: Beyond the Construction Site

While widely used in large building construction, the rebar coil straightening machine has diverse applications. The versatility of a modern rebar straightening and cutting machine allows its use in many sectors.

- Precast Concrete Production: Factories use these machines for precise, volume-based production of pre-tensioned rebar cages.

- Infrastructure Projects: Tunneling and bridge construction require perfectly straight rebar for high-stress structural elements.

- Rebar Distribution Centers: Stocking and distributing straight bars to smaller construction firms is a growing business.

Global Success Story: The Impact of the Bar Straightening Machine Price

Mr. Javier in Mexico faced a challenge. His construction company needed to process high volumes of 12mm rebar. They were losing 15% of material due to poor straightening quality from an old machine. After researching the best bar straightening machine price versus performance, he chose a YG-GW40 model.

The result was immediate and significant. The new machine achieved a material waste reduction of nearly 12%. Furthermore, the higher speed allowed them to complete the steel processing phase two weeks ahead of schedule. Mr. Javier reported a 25% increase in overall site productivity within the first quarter of use. This demonstrates how a sensible investment pays off quickly through efficiency gains.

Customer Common Questions (Q&A) About the Rebar Coil Straightening Machine

The lifespan of the straightening rollers depends heavily on the volume and type of material. High-quality alloy rollers can process 5,000 to 8,000 tons of standard rebar before requiring replacement. Regular lubrication and cleaning will maximize this lifespan.

Yes, the best rebar coil straightening machine models offer quick diameter adjustment mechanisms. Changing from 6mm to 12mm typically takes less than five minutes. Some advanced machines feature automatic adjustment via the PLC control panel.

Most medium-sized machines operate on 380V three-phase power. The required motor power typically ranges from 15kW to 30 kW, depending on the maximum rebar diameter the machine can handle.

Choosing Your Next-Generation Rebar Coil Straightening Machine

Investing in a top-notch rebar coil straightening machine is a surefire way to boost your operational efficiency and achieve a better return on investment. When making this decision, focus on factors like precision (Straightening Tolerance), automation (PLC control), and overall cost-effectiveness, rather than just chasing the lowest price for a bar straightening machine. At YG Machinery, we’re committed to offering machines that enhance your Rebar Processing Productivity while ensuring they remain reliable for the long haul.

Are you ready to take your steel processing to the next level? Get in touch with YG Machinery today! We’d love to chat about your specific diameter and volume needs, and we can provide you with a personalized quote for the perfect rebar straightening machine that fits your project perfectly.