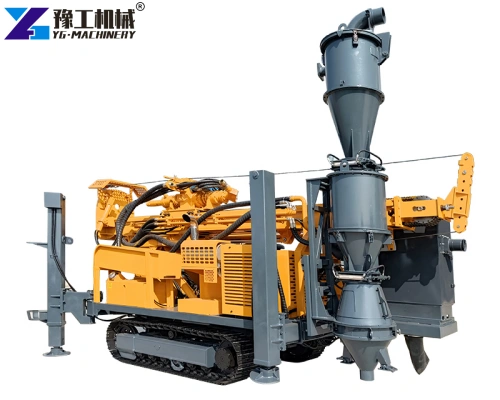

The RC drill rig (Reverse Circulation) represents the pinnacle of modern mineral exploration and grade control technology. Unlike traditional methods, an RC drill rig utilizes a sophisticated dual-wall drill pipe system. This system consists of an outer drill rod and an inner hollow tube. It is designed to recover continuous rock samples without the risk of contamination from the borehole walls.

The mechanics are fascinating. Compressed air is injected through the annular space between the two pipes. This high-pressure air drives a pneumatic hammer that pulverizes the rock. The resulting rock chips are then forced up through the center of the inner tube to the surface. This “reverse” flow ensures that the sample never touches the outside environment until it reaches the cyclone separator. In the competitive mining industry, using a reverse circulation drill rig is often the difference between a profitable project and a failed venture.

RC Drill Rig Parameter

| Technical Parameters | unit | YG-400 | YG-500 | YG-600 | YG-800 | YG-1200 |

| Maximum drilling depth | M | 300 | 400 | 500 | 600 | 1000 |

| Drilling diameter | mm | 105-305 | 105-400 | 105-450 | 105-550 | 105-800 |

| Recommended working air pressure | Mpa | 1.2-3.5 | 1.6-6 | 1.6-6 | 1.6-8 | 1.6-8 |

| Recommended gas consumption | m³/min | 16-55 | 16-55 | 16-75 | 16-96 | 16-96 |

| Drill pipe length | m | 3 | 3 | 3 | 6 | 6 |

| Recommended drill pipe diameter | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| Recommended diameter for air reverse circulation double-walled drill pipe | mm | 89/102 | 102/114 | 102/114 | 114/127 | 127/146 |

| Axial pressure | T | 6 | 7 | 7 | 11 | 13 |

| Lifting force | T | 22 | 25 | 29 | 47 | 57 |

| Rapid ascent speed | m/min | 20 | 23 | 29 | 29 | 30 |

| Fast forward speed | m/min | 32 | 33 | 33 | 42 | 44 |

| Maximum rotational torque | Nm | 8000/4000 | 10000/5000 | 12000/6000 | 18000/9000 | 24000/12000 |

| Maximum rotational speed | r/min | 75/150 | 75/150 | 75/150 | 70/140 | 86/172 |

| Small auxiliary hoisting force | T | 1.5 | 1.5 | 2.5 | 2.5 | 2.5 |

| Drilling efficiency | m/h | 10-35 | 10-35 | 10-35 | 10-35 | 10-35 |

| Walking speed | Km/h | 2.5 | 2.5 | 3.5 | 5 | 6.4 |

| External dimensions | m | 6.2*1.85*2.8 | 7*2.1*2.8 | 7*2.1*2.8 | 10.5.*2.25*3.3 | 11.5*2.25*3.4 |

| Adaptation conditions | Loose layers and bedrock | |||||

| Drilling method | Top-drive hydraulic rotation and propulsion, down-the-hole hammer drilling or mud drilling. | |||||

| Optional accessories | Mud pumps, centrifugal pumps, generators, foam pumps | |||||

RC Drilling vs. Diamond Drilling: A Comparative Analysis

When selecting a drilling method, the debate often centers on RC drill rig vs. Diamond Core drilling. While diamond drilling provides solid core samples, the reverse circulation drill is frequently the superior choice for initial exploration and grade control for several reasons:

- Cost Efficiency: In markets like Australia or South Africa, the cost of diamond drilling can be prohibitively high. An RC drill rig typically reduces costs by 30% to 40%. On average, RC drilling costs range from $35 to $42 per meter, whereas diamond drilling can double that figure.

- Speed and Productivity: Time is money in mining. A reverse circulation drill rig can achieve penetration rates of 200 to 300 meters per day. In contrast, diamond rigs struggle to reach 80 meters in the same timeframe.

- Logistical Simplicity: Because the reverse circulation drill uses air rather than water for cooling and chip removal, it is ideal for remote, arid regions. You don’t need a massive water truck fleet to keep the operation running.

Core Advantages of RC Drill Rig: Supported by Accurate Data

High Drilling Efficiency

RC drill rig can drill 200-300 meters per day, which is 2-3 times higher than core drilling rigs. This efficiency advantage shortens the exploration cycle significantly, helping enterprises obtain geological data faster and accelerate project progress.

Low Cost Advantage

Compared with diamond drilling, the cost of RC drill rig can be reduced by up to 40%. Taking Australia as an example, the drilling cost per meter is about 35-42 US dollars, including transportation, consumables and labor costs.

Reliable Sample Quality & Environmental Protection

The cuttings collected by RC drill rig are not contaminated by external environments, ensuring accurate positioning of mineralized zones. Modern RC drill rigs, such as those produced by YG Machinery, are equipped with dust collectors that can collect over 90% of drilling dust, avoiding environmental pollution.

Strong Adaptability to Working Conditions

RC drill rig does not require water during operation, making it suitable for water-scarce areas such as deserts and arid mining areas. Its compact structure requires little earthwork, minimizing environmental impact.

Hydraulic Compensation System

The drill frame makes direct contact with the ground. This minimizes vibration and maximizes structural rigidity.

Advanced Air Pre-filter

Our patented system filters over 90% of intake dust. It significantly reduces engine wear and extends the machine’s lifespan.

Automated Handling

Integrated hydraulic wrenches and rod lifters make the process safer. It reduces manual labor and speeds up pipe changes.

Wide Application Scenarios of RC Drill Rig

Mining Industry: Grade Control

RC drill rig is the best choice for open-pit mining grade control. It can accurately distinguish waste rock from minerals, reducing mining costs. It is widely used in gold, iron, copper and other metal mines in Australia, South Africa and other countries.

Geological Exploration

In geological exploration projects, RC drill rig is used to collect stratum samples for mineral resource evaluation. Its cyclone separator can effectively collect cuttings, which is essential for geological analysis institutions.

Water Conservancy & Hydropower Engineering

RC drill rig is applied in groundwater exploration and foundation investigation of water conservancy projects. It can drill stably in gravel and cobblestone layers, providing reliable data for project design.

Oil & Gas Exploration

In shallow oil and gas exploration, reverse circulation drill is used for stratum sampling. Its low environmental impact and high efficiency make it suitable for exploration projects in ecologically sensitive areas.

Water Well Construction

Efficiently creates large-diameter wells in fractured rock formations without borehole collapse.

Overseas Success Cases of YG Machinery RC Drill Rig

Case 1: Gold Mine Exploration in Western Australia

Client: Tom, a mining engineer from a gold mining enterprise in Western Australia. The client faced problems of low exploration efficiency and high water consumption in the arid gold mining area.

Solution: YG Machinery provided a customized RC drill rig with a patented air pre-filter. This equipment can filter over 90% of dust in the intake air and operate without water.

Results: The drilling efficiency increased by 60% compared with the original equipment, completing 250 meters of drilling per day. The water cost was reduced by 100%, and the sample qualification rate reached 98%. The project cycle was shortened by 3 months, saving 400,000 US dollars in total costs.

Case 2: Mineral Exploration in South Africa

Client: Sarah, a project manager of a geological exploration company in South Africa. The client needed equipment that could adapt to complex stratum conditions and ensure operator safety.

Solution: The RC drill rig provided by YG Machinery adopts full hydraulic control, including drill frame lifting, drill pipe handling and other functions, reducing labor intensity. It is also equipped with complete safety protection devices such as hearing protectors and breathing masks.

Results: The equipment operated stably in complex strata such as gravel and hard rock. The labor intensity of workers was reduced by 50%, and no safety accidents occurred during the whole project. The exploration data was accurate, helping the client successfully identify a new copper ore body.

Common Q&A About RC Drill Rig

RC drill rig is suitable for various strata, including soil, sand, gravel, cobblestone and hard rock with compressive strength up to 200MPa. It can achieve efficient drilling through pneumatic percussion technology.

Focus on equipment adaptability to your working conditions, such as whether it is suitable for water-scarce or high-dust environments. Check the quality of key components such as hydraulic systems and air filters. In addition, consider after-sales service and spare parts supply to ensure long-term stable operation.

No. Rock chips travel inside the inner tube, isolated from the borehole walls. This guarantees the chemical integrity of every sample collected.

About YG Machinery: Your Global Mining Partner

As a premier machinery manufacturer with over 20 years of expertise, YG Machinery has delivered thousands of drilling units to more than 100 countries worldwide. Our 50,000-square-meter production facility is equipped with advanced CNC machining centers, ensuring that every RC drill rig meets rigorous international quality standards. We provide more than just equipment; we offer comprehensive solutions ranging from rapid spare parts supply to on-site technical training. Choosing YG means investing in reliability, extreme efficiency, and dedicated after-sales support.

Ready to Scale Your Drilling Efficiency? If you are searching for a high-performance reverse circulation drill rig for sale, contact our expert team today. We offer customized configurations tailored to your specific geological challenges and project requirements.