A reliable hydraulic thread rolling machine is essential for modern construction projects that require strong and fast rebar connections. Many contractors want a machine that delivers precise threads, reduces labor time, and keeps structural quality high. This machine offers a simple way to improve connection strength and speed on any site.

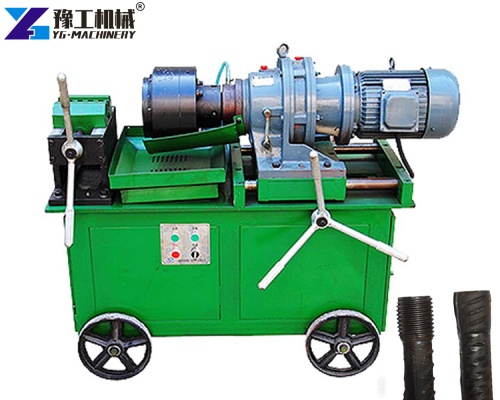

At YG Machinery, our hydraulic thread rolling machine is designed for stability, long service life, and high accuracy. With the right setup, it produces clean and full threads that ensure excellent connection performance.

Hydraulic Thread Rolling Machine Parameter:

| Model | YGS-40 | YGT-40 | YGA-40 |

| Processing diameter range | 16-40mm | ||

| Thread rolling length | 0-80mm | 0-80mm | 0-100mm |

| Power voltage | 4kw/380v 50hz | 4kw/380v 50hz | 7.5kw/380v 50hz |

| Working efficiency | 15s/forming | 8s/forming | One-touch auto forming |

| Machine weight | 320kg | 350kg | 400kg |

| Machine size | 115*50*106cm | 110*60*130cm | 126*70*106cm |

| Type | Standard type | Upgrade type | Full automatic type |

What the Hydraulic Thread Rolling Machine Does

Easy Threading With High Accuracy

A hydraulic thread rolling machine forms standard rebar threads by rib-peeling and rolling under controlled hydraulic force. The hydraulic unit keeps the rolling pressure stable, which helps the machine form consistent threads.

It works for rebar diameters from 16–40 mm. The machine can complete peeling and threading in one setup. The full tooth shape improves tension strength and helps reduce construction risks.

Core Technical Advantages

- The threads have high precision and full profile.

- The hydraulic force creates a smooth rolling process.

- It supports forward and reverse threads.

- No cutting of the base material. The thread strength is higher than the rebar itself.

- One operator can easily run the machine with minimal training.

These points make the machine ideal for contractors who want stable operation and uniform results.

Why Contractors Prefer This Machine

Stronger Rebar Connections

The rolling method increases thread strength. The finished joint maintains high tensile, fatigue, and corrosion resistance. This helps contractors build safer and longer-lasting structures.

Faster Work and Lower Labor Demand

One machine can process many joints per hour. A stable hydraulic system cuts downtime and reduces the need for skilled operators.

Better Cost Control

Because the machine does not damage the rebar, material waste is low. Simple operation also reduces manpower requirements.

Hydraulic Thread Rolling Machine FAQ

Most joints take about one minute, depending on diameter and thread length.

Yes. Many customers also use a rebar straightening machine, hydraulic rebar bender, or rebar upsetting machine for a full production line.

The hydraulic thread rolling machine focuses on power and stability. An automatic thread rolling machine offers quicker feeding and less manual work.

YG offers a fair thread rolling machine price, based on size, configuration, and roller type.

Many customers ask how to choose a suitable machine. The key is to confirm the rebar type, diameter range, and thread length. You also need to check the duty cycle and hydraulic pressure. If your project needs large-volume processing, choose a machine with strong power and durable rollers. YG’s team can recommend the best setup based on your drawings.

Thread errors often come from worn rollers or incorrect adjustments. You should calibrate the peeling blade before rolling. Always match the roller pitch with the coupler. YG provides clear guides, and our technicians help you solve issues through online support.

Where the Hydraulic Thread Rolling Machine Is Used

The machine serves many construction and industrial fields. It works well in:

- Residential and commercial buildings

- Bridges, tunnels, and highways

- Precast concrete plants

- Steel structure projects

- Industrial plants and infrastructure

Any project that requires strong mechanical rebar connections benefits from using a hydraulic thread rolling machine.

Case Study: A Successful Project in Turkey

A contractor named Musa from Turkey needed a fast and clean threading solution for a large bridge reinforcement project. His team had issues using an older machine due to inconsistent thread shape and high labor demand.

After reviewing the job size and rebar types, he chose a hydraulic thread rolling machine from YG. The machine processed 16–40 mm rebar with stable thread accuracy. The full thread shape allowed for reliable coupler installation.

Results he reported:

- Processing speed improved by 40%

- Labor reduced from 3 workers to 1 operator

- Thread quality became consistent

- No damage to the rebar body

- Less downtime due to stable hydraulic control

Musa later expanded his equipment line and added a thread rolling machine for sale from our upgraded series.

This case reflects the strong demand for this equipment in Turkey, UAE, Saudi Arabia, Brazil, and many European markets.

How to Extend Machine Service Life

To extend service life, keep the hydraulic oil clean and change it on schedule. Check roller wear and keep all internal shafts lubricated. Good maintenance helps the hydraulic thread rolling machine maintain fast speed and accurate threads. YG supplies spare parts for long-term use.

Why YG Machinery Is a Trusted Supplier

YG Machinery provides stable quality, complete certifications, and reliable support. Our machines are used in many countries. We help with:

- Pre-sale consultation

- Machine configuration planning

- Online technical support

- Spare parts supply

- Long-term maintenance guidance

Customers often note the machine’s smooth performance and stable accuracy. One client from Mexico shared that his team increased daily output by over 30% after switching to YG’s hydraulic model.

Get Your Quote Today

If you want strong, fast, and reliable rebar threading, the hydraulic thread rolling machine is a practical choice. Tell us your rebar size and project needs.

We will send a detailed plan and offer.

Contact YG Machinery now for a free quote and custom solution.