Are you currently searching for the latest diamond wire saw price? Do you know how to choose a model that matches your project needs while controlling costs? The diamond wire saw is the core tool for heavy static concrete cutting, efficiently handling large-scale, complex structures that traditional methods (such as blasting or hammering) struggle to tackle—including underwater concrete piles, massive bridge piers, and nuclear power plant structural modifications. YG Machinery delivers high-performance, customized cutting solutions to global clients (covering the USA, South Africa, Southeast Asia, and more). This article will break down key factors influencing diamond wire saw prices, provide detailed model comparisons, and share practical selection and ROI calculation methods to help you make a cost-effective investment decision. Need a free project evaluation and custom quote? Contact our expert team now for tailored technical consultation!

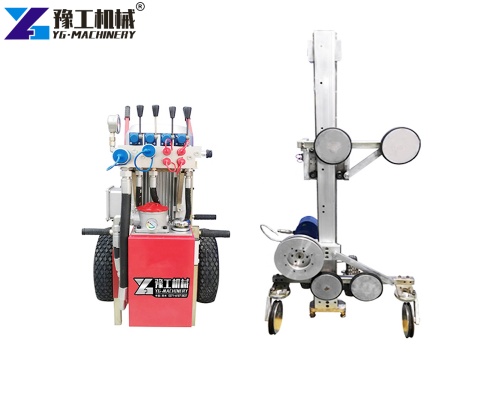

Hydraulic Diamond Wire Saw Machine Parameter:

| Diamond Wire Saw Parameters | Hydraulic Pump Station Parameters | ||

| Wire drive mode | hydraulic | Rated output power | 22/25kw |

| Mode type | HM-40/80 | Working voltage | 380v50Hz |

| Minimum input power | 25/33HP | Hydraulic pump station | gear pump |

| Output shaft speed | 350/940/1300r/min | Motor working flow | 40-100L/min |

| Maximum wire length | 18m | Working pressure | 15-20Mpa |

| Enter method | fully hydraulic | Oil tank volume | 17L |

| Cutting machine weight | 64kg | Weight | 98kg |

| Motor weight | 14kg | Dimension(mm) | 650*550*1150 |

Understanding the Technical Value Behind the Diamond Wire Saw Price

The core strength of YG’s diamond wire saw lies in its versatility + efficiency + durability, which directly justifies its price positioning:

- Cutting Versatility: It can achieve irregular cuts (curves, holes), deep cuts (over 10m), and underwater cuts—scenarios where hydraulic wall saws (limited to flat, precise cuts like door/window openings) cannot compete. For example, in underwater bridge pier modifications, the wire saw’s sealed design and abrasive-resistant beads ensure stable operation without water leakage.

- Efficient Hydraulic System: Equipped with a high-performance hydraulic power unit, it maintains a constant high rotation speed (up to 1300r/min) even under heavy loads. Compared to ordinary electric wire saws, YG’s models improve cutting efficiency by 40%—completing 30 cubic meters of concrete cutting per day, while reducing project timelines by 20-30%.

- Long-Term Cost Savings: The machine adopts high-density diamond-impregnated beaded wires and high-strength galvanized steel frames, reducing bead replacement frequency by 50% and equipment failure rate to less than 2% per year. This lowers the total cost of ownership (TCO) by 30% compared to low-cost, low-quality alternatives.

Diamond Wire Saw Price FAQ

The price difference mainly depends on the machine’s hydraulic power output and automation level. For instance, our models range between $8000 and $15000 usd. This reflects varying power and feature configurations.

You should focus on the cutting depth, wire speed, and beaded wire quality. These parameters directly determine your cubic meter cut rate.

A hydraulic wall saw is mostly used for precise flat cuts, like door or window openings. Conversely, the diamond wire saw is used for irregular, deep, or underwater cuts. The wire saw offers much higher flexibility.

Key Factors Influencing the Diamond Wire Saw Price Analysis

1. Beaded Wire Quality and the Diamond Wire Saw Price

The beaded wire quality is the number one factor impacting the diamond wire saw price. The abrasive resistance of the diamond beads determines their lifespan. High-quality beads require less frequent replacement. This significantly lowers your total cost of ownership. Always look for wire with high-density diamond impregnation.

2. Hydraulic Power Output and Cutting Efficiency

The machine’s hydraulic power output directly influences the cutting speed. Higher power means a faster cubic meter cut rate. Although high-power models May have a higher initial diamond wire saw price. The efficiency gains and reduced project timelines offer far greater returns.

3. Component Durability and Long-Term Cost

Component durability is vital for determining the total cost of ownership. We use high-strength galvanized steel frames. High-quality hydraulic motors ensure long-term, stable operation. A reliable machine means fewer breakdowns and repairs. This keeps your diamond wire saw for sale project profitable continuously.

Wide Applications and Success Stories

The investment in the diamond wire saw price is especially worthwhile in large infrastructure projects. It is widely used in the modification of bridges, dock platforms, and nuclear power plant structures.

Brazil: Deep Concrete Demolition on Port Docks

In Rio de Janeiro, Brazil, a port upgrade project required the demolition of a large dock platform. Traditional blasting would have damaged nearby facilities. The client chose YG’s concrete wire saw. The project manager, Marcos, praised the system’s static cutting capability. The machine accurately performed deep concrete demolition. This avoided structural damage and significantly reduced the construction time.

Singapore: Underwater Bridge Pier Cutting

In Singapore, elevated bridge piers required underwater structural modifications. The client needed a reliable diamond wire saw for concrete. The abrasive resistance and sealing of the machine were paramount. YG’s wire saw performed excellently in the submerged environment. It ensured the structural integrity of the main bridge. This validated the added value of high-quality equipment.

How to Calculate the ROI of the Diamond Wire Saw Price

When calculating roi, look beyond the initial diamond wire saw price. You must consider the cubic meter cut rate, labor costs, and downtime. An efficient wire saw saves massive amounts of labor and time. This makes the total cost of ownership far lower than a cheap, inefficient machine. We advise you to focus on cutting performance, not the lowest price tag.

YG Machinery: Your Expert in Diamond Wire Saw For Concrete

We provide custom diamond wire saw for concrete solutions. We understand the varying infrastructure needs across different regions (like the USA, South Africa, and Southeast Asia). Our commitment is to deliver machines with high component durability. We ensure your investment provides true value.

Customer Testimonial

“The YG concrete wire saw was not the cheapest on the market. But the cubic meter cut rate and extremely low failure rate it provided made our total cost of ownership the lowest.” – john, head of demolition, USA.

Take Action: Get Your Custom Diamond Wire Saw Price Quote!

Your project demands accurate, efficient, and reliable cutting equipment. Do not let low-price temptation jeopardize your project schedule. Investing in a YG diamond wire saw is investing in efficiency and reliability. Contact our expert team now for a customized diamond wire saw price quote and technical consultation tailored to your project needs. Let us help you successfully complete your next major demolition task!