Hey there! Is your settling tank not performing as well because of sludge buildup? Dealing with thick sludge can often be costly and risky. If you’re on the lookout for a more straightforward and budget-friendly solution, you’ve come to the right spot. At YG Machinery, we bring years of industry expertise to the table, and we’re excited to help you find the perfect dredging plan tailored just for you.

Why is Sedimentation Tank Dredging a Focus for Plant Maintenance?

In industrial production, sedimentation tanks are responsible for filtering impurities. However, solid waste continues to settle at the bottom. If you do not perform regular sedimentation tank dredging, the treatment capacity of the tank will shrink significantly. This not only pollutes the water source but may also damage downstream pumping equipment. Therefore, choosing an efficient cleaning method is very important for the long-term operation of the plant.

Method 1: Deploy a Wastewater Sludge Removal Robot for 24/7 Operation

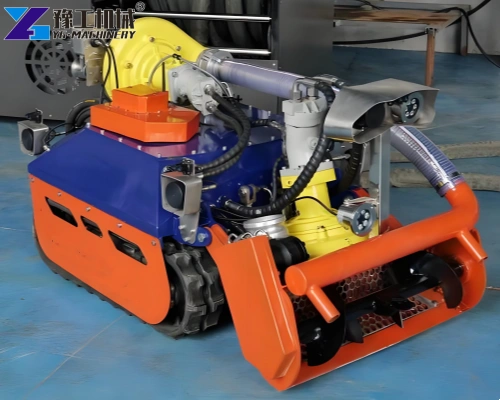

The most recommended method is to use automated equipment. You can deploy a professional wastewater sludge removal robot . This machine can dive directly underwater for sedimentation tank dredging. It does not need to drain the tank, so your production line can continue to run. Additionally, the robot is equipped with high-precision cameras. The operator can easily control it from the shore. This method is not only efficient but also very safe.

Method 2: Use an Industrial Dredging Robot for High-Difficulty Environments

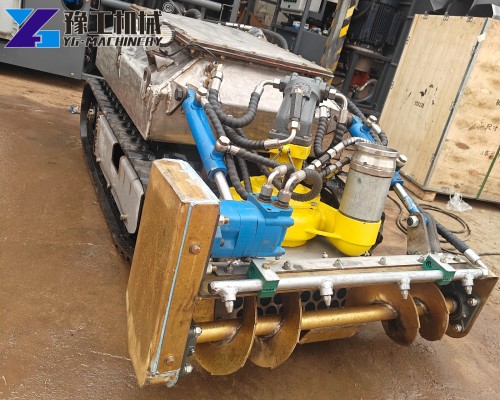

For harsh environments like chemical plants or mines, the method will be different. At this time, we define the machine as an industrial dredging robot. When performing this type of sedimentation tank dredging task, the machine must face corrosive liquids. YG Machinery robots use special stainless steel and anti-corrosion coatings. This means it can work for a long time in strong acid or alkali environments. For heavy industrial customers, this is the most durable choice.

Method 3: Use a Sewage Tank Cleaning Robot to Solve Narrow Space Problems

If your sedimentation tank is located underground or in a limited space, the third method is to use a sewage tank cleaning robot. Although it is the same machine as the first two, it emphasizes flexibility. When performing sedimentation tank dredging in such confined spaces, the compact design of the machine plays a role. It can easily pass through narrow manholes. Furthermore, its powerful track system can climb over obstacles, ensuring no dead corners in the cleaning work.

By now, you’ve probably noticed just how adaptable our robots are. Whether your tank is set up indoors or outdoors, or if it’s deep or shallow, YG has got you covered. If you’re unsure about which configuration would work best for your situation, don’t hesitate to reach out to us anytime. We’d be happy to provide you with a video demo showing how the machine operates.

Method 4: Use Submersible Slurry Pumps for High-Pressure Suction

If you have a limited budget, the fourth method is to use high-power submersible pumps. This way of sedimentation tank dredging is quite direct. Workers lower the pump to the bottom and suck the slurry out with high pressure. Although this method is faster than manual work, the pump location is fixed. It often fails to clean dead corners far away. Also, if the sludge is too thick, the pump can clog easily.

Method 5: Traditional Draining and Manual Cleaning

The last method is to drain the water and then have workers dig manually. This is the oldest way of sedimentation tank dredging. However, we usually do not suggest that customers do this. First, draining the tank means you must stop production, which causes a huge loss. Second, toxic gases may exist at the dredging site, which is a big threat to workers’ health. In contrast, investing in a YG robot has an upfront cost but avoids these potential risks.

Why Choose YG Machinery Dredging Equipment?

We are committed to making sedimentation tank dredging much simpler. The YG Machinery product line covers all types of robots from small to large. Our machines are not only powerful but also very easy to maintain. Since we are a direct factory supplier, you can get a very competitive price. More importantly, we provide detailed training to ensure your staff can quickly start operating the machine.

Key Precautions During the Dredging Process

No matter which method you choose, safety is always first. Before starting sedimentation tank dredging, please make sure to test the air quality. Also, protecting the concrete tank wall is very important. Our robots use rubber tracks, which can effectively protect the tank bottom from scratches. At the same time, proper sludge dewatering can help you save a lot of transportation costs.

In summary, although there are many dredging methods, automated robots are undoubtedly the future trend. It saves you labor, time, and money. If you are planning your next sedimentation tank dredging task, please consider YG’s smart solutions. We have thousands of successful application cases and can provide you with valuable experience.

Thank you for reading this article! If you are interested in our dredging robots or want to know more technical details, please email us now. We do not just sell machines; we provide a complete set of dredging solutions for you. We look forward to your inquiry, and let us make the work more efficient together!