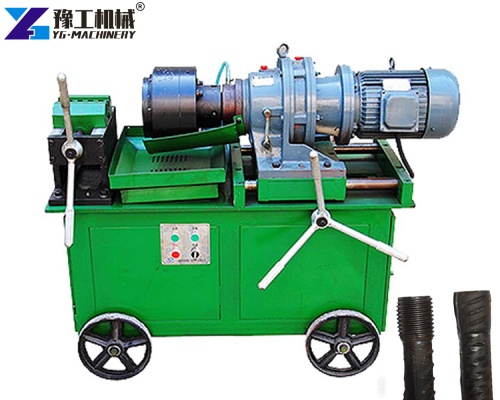

If you’re on the lookout for top-notch, efficient equipment for processing steel bar threads, then an automatic thread rolling machine is just what you need. YG Machinery’s automatic thread rolling machine is designed to handle rebar sizes from 16 to 40mm and has already made its mark in over 30 countries, including the US and Germany. It can produce between 30 to 40 pieces per hour, which can help clients save up to 40% on construction time.

Automatic Thread Rolling Machine Parameter:

| Model | YGS-40 | YGT-40 | YGA-40 |

| Processing diameter range | 16-40mm | ||

| Thread rolling length | 0-80mm | 0-80mm | 0-100mm |

| Power voltage | 4kw/380v 50hz | 4kw/380v 50hz | 7.5kw/380v 50hz |

| Working efficiency | 15s/forming | 8s/forming | One-touch auto forming |

| Machine weight | 320kg | 350kg | 400kg |

| Machine size | 115*50*106cm | 110*60*130cm | 126*70*106cm |

| Type | Standard type | Upgrade type | Full automatic type |

Automatic Thread Rolling Machine: 4 Core Application Scenarios

Construction Engineering

Rebar connection processing in high-rises and residential projects, one-time forming without open flame.

Practical tip: Pair with rebar couplers for joint strength 20% higher than base metal.

Bridge & Tunnel Projects

Process large-diameter rebar (32-40mm), cold rolling boosts thread fatigue strength by 60%.

Practical tip: Activate the built-in cooling system to avoid precision loss from high temperatures.

Industrial Manufacturing

Produce mechanical parts and fasteners, supporting HRB335/HRB400 rebar with 6H thread precision.

Practical tip: Choose a hydraulic thread rolling machine for high-strength metal processing.

Prefabricated Component Factories

Bulk rebar processing for precast beams/walls, automatic feeding reduces manual intervention.

Practical tip: Enable auto-counting to simplify production capacity tracking.

YG Automatic Thread Rolling Machine: 4 Core Advantages

High Efficiency & Automation, Save Labour Costs

Integrated auto-feeding, rib stripping, and threading—operated by one person, 5x faster than manual.

Practical tip: Add an auto-loading rack for 24-hour continuous processing.

High Precision, Reliable Joint Quality

Thread precision error ≤0.05mm, consistent diameter, meeting US/EU construction standards.

Practical tip: Check rolling die wear regularly to maintain stable precision.

Durable Structure, 8+ Year Service Life

4kw motor-driven, high manganese steel body, 8-hour daily trouble-free operation.

Practical tip: Clean the cooling system monthly to extend core component life.

Flexible Adaptation, Multi-Spec Processing

Supports 16-40mm rebar, max processing length 80mm (custom 25cm extended version available).

Practical tip: Replace rolling dies to switch between rebar diameters quickly.

Success Stories: Efficiency Boost from US & Germany Clients

US: Mike’s Construction Project Cuts 40% Time

Mike, a Texas contractor, faced two issues with manual machines:

- 3 workers operated one machine, only 8pcs/hour, failing to meet deadlines;

- Unstable thread precision, 85% joint pass rate, frequent rework.

He chose YG’s automatic thread rolling machine with auto-feeding:

- 1 worker achieves 35pcs/hour, labour costs reduced by 67%;

- 99.8% thread pass rate, zero rework, project finished 20 days early.“This machine makes us stand out,” Mike said. “We use it for every project now.”

Germany: Thomas’s Prefab Factory Doubles Capacity

Thomas ran a precast factory, needing bulk processing of 32mm large-diameter rebar.

His old machine took 3 minutes per piece, with poor cooling causing thread deformation.

After adopting YG’s automatic thread rolling machine:

- Processing time down to 90 seconds per piece, daily capacity from 120 to 280pcs;

- Built-in cooling system controls temperature, thread deformation ≤0.03mm.“We found YG via a thread rolling machine for sale,” Thomas shared. “It meets EU standards perfectly.”

Automatic Thread Rolling Machine FAQ

Standard 16-40mm rebar; custom extended version handles up to 25cm workpieces.

30-40pcs/hour normally; 50pcs/hour with an auto-loading rack.

Annual maintenance cost <5% of equipment price; rolling dies (8000pcs service life).

Equipment, operation manual, basic dies, and 24/7 remote technical support.

Complies with ISO, ANSI, DIN standards, passing global project inspections.

Core Technical Advantages of the YG Automatic Thread Rolling Machine

Cold Rolling Technology, Enhance Thread Strength

Cold rolling hardens threads, increasing tensile strength by 20-30% and fatigue strength by 40-60%.

Technical highlight: No heat treatment, retaining the rebar’s original toughness.

Automatic System, Easy Operation

“Fool-proof” rib stripping device, new users master in 1 hour. Auto-feeding/retracting reduces errors.

Technical highlight: PLC control system stores parameters for repeated use.

Cooling System, Support Continuous Processing

Built-in circulating cooling system lowers temperature, preventing thread deformation.

Technical highlight: Reusable coolant reduces consumable costs.

YG’s Global Reach & Service Guarantee

YG’s automatic thread rolling machine is widely used beyond construction:

- US: Designated equipment for large residential and bridge projects;

- Germany: Preferred choice for precast component factories;

- UAE: Core equipment for Dubai’s infrastructure projects.

We offer 3 core guarantees:

- Free technical consultation: Recommend suitable models based on project needs;

- Detailed training: Video tutorials + manuals for quick setup;

- 1-year warranty: Free core part replacement + 24/7 remote support.

Get Your Custom Plan Now

Want to boost efficiency like Mike and Thomas? Contact YG Machinery for:

- Free equipment adaptation advice;

- Transparent thread rolling machine price breakdown;

- Local success case videos (US, Germany, EU).

WhatsApp/WeChat: +86 13837112713. We respond in 1 hour—let the automatic thread rolling machine cut your costs and boost competitiveness!