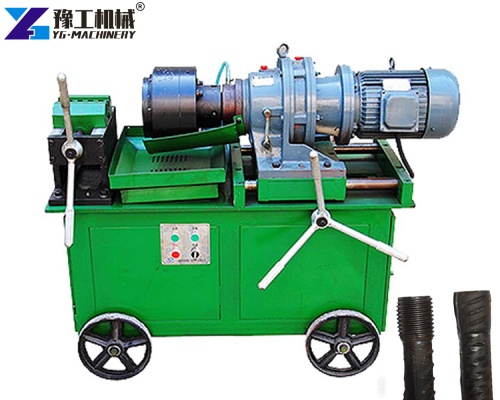

When you search for the thread rolling machine price, you are evaluating an investment in maximizing metal cold forming efficiency. YG Machinery’s thread rolling machines use advanced cold rolling technology. This process is more efficient than cutting and significantly boosts thread fatigue strength. Our goal is to offer you the most competitive thread rolling machine price while ensuring outstanding performance.

Thread Rolling Machine Price Parameter:

| Model | YGS-40 | YGT-40 | YGA-40 |

| Processing diameter range | 16-40mm | ||

| Thread rolling length | 0-80mm | 0-80mm | 0-100mm |

| Power voltage | 4kw/380v 50hz | 4kw/380v 50hz | 7.5kw/380v 50hz |

| Working efficiency | 15s/forming | 8s/forming | One-touch auto forming |

| Machine weight | 320kg | 350kg | 400kg |

| Machine size | 115*50*106cm | 110*60*130cm | 126*70*106cm |

| Type | Standard type | Upgrade type | Full automatic type |

Core Price Driver: Quantifying Rolling Force and Maximum Diameter

The rolling force is the most critical factor determining the thread rolling machine price.

- Rolling Force: Our machine models offer $15 \text{tons}$ to $30 \text{tons}$ of rolling force (that’s powerful! ⚙️). The higher the force, the higher the price.

- Maximum Rolling Diameter: The cost is directly proportional to the maximum rolling diameter the machine can handle (e.g., $\phi 6 \text{mm}$ to $\phi 50 \text{mm}$).

- Tip: Choose a model with $10\%$ more rolling force than your current maximum requirement. This ensures future adaptability.

Technology Choice: Why Hydraulic Thread Rolling Machine Costs More

A hydraulic thread rolling machine typically has a higher initial cost than a mechanical machine, but it offers better value.

- Hydraulic Advantage: The hydraulic thread rolling machine provides stable and controllable rolling force. This is essential for ensuring thread profile consistency and superior thread quality.

- Pressure Stability: The hydraulic system ensures stable working pressure. This reduces stress on the rolling dies and machine components.

- Tip: If your work involves high-precision or large-diameter rebar (over $\phi 25 \text{mm}$), opt for the hydraulic system.

Quality Assurance: Cold Rolling Boosts Thread Quality and Strength

Cold rolling (Thread Rolling) is forming, not cutting. This is critical for end-product performance.

- Strength Boost: The cold rolling process increases the metal density at the thread root. Thread strength and fatigue life can increase by up to $30\%$.

- Thread Quality: Rolled threads have a much better surface finish. There are no cutting marks, eliminating stress concentration points.

- This superior thread quality makes it the preferred choice for applications demanding high reliability.

Output & Efficiency: Maximizing Production Rate and Reducing Waste

A high production rate is key to quickly recouping the thread rolling machine price.

- Production Rate: Our machines can complete one piece of threading in approximately $8 \text{seconds}$. This achieves a production rate of up to $6 \text{threads}$ per minute.

- Waste Control: Cold rolling is a chipless process. Material waste is kept below $1\%$. ♻️

- Setup Time: Quick-change tooling design allows roll replacement and setup time of less than $30 \text{minutes}$.

TCO Analysis: Tool Life and Maintenance Costs

Evaluating the thread rolling machine price must include the long-term total cost of ownership (TCO).

- Tool Life: High-quality roll dies can achieve a tool life of $10,000$ to $20,000$ parts per roll set. This is much longer than cutting tools.

- Maintenance Costs: Hydraulic machines are simpler to maintain. The heavy-duty structure provides excellent vibration dampening.

- Lower tooling costs and reduced downtime make the TCO extremely competitive.

Application Expansion: From Construction to Automotive Fasteners

Thread rolling machines are vital equipment across multiple industries.

- Construction: Used for rebar splicing, anchor bolts, and structural connections. 🏗️

- Automotive: Manufacturing high-strength bolts, tie rods, and critical fasteners.

- Oil & Gas: Creating high-pressure, high-fatigue resistant pipe couplings.

Integrated Solution: Pairing with Rebar Straightening Machine

For the highest thread quality, material preparation is crucial.

- Material Requirement: Thread rolling demands high straightness and consistent diameter from the material.

- Paired Use: Your rebar straightening machine must ensure the rebar is perfectly straight before entering the roller.

- We recommend purchasing the full solution to guarantee optimal thread quality and maximum efficiency. 🔗

Durability & Cooling: Oil Cooling System and Vibration Dampening Performance

Machine reliability ensures continuous profitability.

- Oil Cooling System: This system ensures the hydraulic oil maintains a stable temperature during extended, high-intensity work. It prevents premature wear of hydraulic components. 🌡️

- Vibration Dampening: The heavy-duty frame and high-quality mounting pads absorb over $95\%$ of machine vibration. This protects the rolling dies and the operator.

- These features enhance the machine’s lifetime reliability.

Success Case Study: Klaus in Germany

Klaus is a production manager for a large precast concrete company in Germany. He needed a fast way to produce high-strength $20 \text{mm}$ threaded rebar. 🇩🇪

- The Challenge: Traditional cutting was too slow and failed to meet the required thread strength standards for precast applications.

- The Solution: Klaus invested in a $25 \text{tons}$ rolling force hydraulic thread rolling machine from YG.

- The Outcome: He achieved a stable production rate of $5 \text{threads/min}$. Thread strength increased by $25\%$ over cutting. This justified the higher thread rolling machine price.

Get Your Custom Thread Rolling Machines Quote

The thread rolling machine price is a metric for your future productivity. YG Machinery offers thread rolling machines that deliver $15 \text{tons}$ of rolling force and $30\%$ thread quality boost. We ensure low TCO and high lifetime reliability.

Contact YG Machinery today to get your custom hydraulic thread rolling machine quote based on your maximum rolling diameter and required production rate!