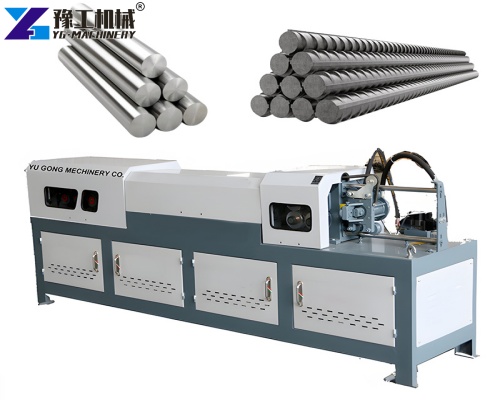

When you search for the rebar straightening machine price, you are looking for more than a sticker price. You are looking for an investment that boosts project efficiency and minimizes waste. YG Machinery’s rebar straightener machine series is designed to offer exceptional total cost of ownership (TCO). We cover everything from portable rebar straightener units to industrial full automatic cutting systems. Our goal is to provide you with the most competitive rebar straightening machine price possible.

Technical Parameters of Rebar Straightening Machine Price

| Model | YGT 4-14 | YGT 5-16 |

| Diameter adjustment range | 4-14mm ( Ⅲ grade steel) | 5-16mm ( Ⅲ grade steel) |

| Wire pulling speed | 50m/min | 50m/min |

| Traction motor power | 2.2kw-6 | 2.2kw-6 |

| Modulation motor power | 7.5kw-4 | 15kw-4 |

| Cut off motor power | 5.5kw | 5.5kw-4 |

| Cutting error | ±0.5-1cm | ±0.5-1cm |

| Wire Length | 800-9000mm (can be lengthened) | 800-9000mm (can be lengthened) |

| straightening degree | ±2 mm/m | ±2 mm/m |

| Weight | 1500kg | 1500kg |

| Size | 2800*650*1200mm | 3300*650*1300mm |

Core Factors: The Three Variables Driving Rebar Straightening Machine Price

The fluctuation in rebar straightening machine price is not random. It is driven by three key specifications:

- Maximum Diameter: The largest rebar diameter the machine can handle (e.g., $\phi 4 \text{mm}$ up to $\phi 14 \text{mm}$). Larger diameters require higher motor power ($7.5 \text{kW}$ to $11 \text{kW}$) and increase the cost.

- Wire Feeding Speed: Standard speeds are often $30 \text{m/min}$, while high-speed models can reach $100 \text{m/min}$. Higher speed means higher output and a higher price tag.

- Technology Type: Rotary (older) versus Roller (newer). Roller technology generally offers superior straightening precision but comes at a slightly higher cost.

Technology Determines Accuracy: Quantifying Straightening Precision

The mechanism your rebar straightener uses directly affects the quality of the final product.

- Straightening Precision: Our roller-type systems control straightness error to within $\pm 2 \text{mm/m}$. This high precision is vital for meeting the strict demands of high-rise construction or prefabrication.

- Rotary Drawback: Rotary systems rely on friction, which can potentially damage the rebar surface and compromise straightening precision.

- Practical Advice: Investing in a machine with higher straightening precision can reduce material waste by $5\%$ or more.

Calculating Total Cost of Ownership (TCO): The Long-Term ROI

The true rebar straightening machine price must factor in long-term operational costs.

- Labor Savings: One machine requires only $1$ operator. This reduces labor costs by up to $90\%$ compared to manual or simplified methods.

- Energy Efficiency: Focus on low-consumption models. Ask for the $\text{kWh}$ consumption per ton of straightened rebar before buying.

- Maintenance Costs: Simple mechanical components like cutters and guides are easy to replace. This significantly lowers long-term maintenance costs.

Productivity Boost: High Wire Feeding Speed and Automatic Cutting

Time is money. An efficient rebar straightener must be fast and continuous.

- Wire Feeding Speed: Our standard rebar straightener machine offers a stable speed of $60 \text{m/min}$.

- Output: Even medium-sized models can process over $6 \text{tons}$ of rebar per shift.

- Automatic Cutting: Integrating an automatic cutting system eliminates manual measuring and shearing, increasing overall production efficiency by $20\%$.

Durability & Longevity: Ensuring Motor Power and Lifetime Reliability

Sufficient motor power is key to guaranteeing lifetime reliability.

- Motor Power: Ensure the motor power (e.g., $11 \text{kW}$) matches the machine’s maximum diameter capacity. Using an underpowered machine risks premature failure.

- Lifetime Reliability: Our core components (straightening rollers, cutters) are made of hardened alloy steel ($\text{HRC60}$ or higher). The Mean Time Between Failures ($\text{MTBF}$) can reach $\geq 1000 \text{hours}$.

- A robust frame design withstands high-intensity vibration, extending the machine’s overall service life.

Application Scenarios: From Residential to Infrastructure

The rebar straightener is essential across various construction phases.

- Prefabrication Factories: Require extremely high straightening precision (e.g., $\pm 1 \text{mm/m}$).

- Large Infrastructure: Requires high wire feeding speed models to meet bulk volume demands.

- Residential Construction: Smaller, portable rebar straightener machine models are easy to transport between job sites.

The Complete Solution: Integrating with Hydraulic Thread Rolling Machine

Maximizing rebar processing profit comes from offering a full solution.

- Paired Use: After straightening the rebar, use a hydraulic thread rolling machine to quickly create high-quality, high-strength threads.

- Advantage: The hydraulic thread rolling machine increases joint strength and saves welding time.

- Combining these two pieces of equipment elevates your rebar fabrication capabilities to the next level.

Success Case Study: Amir in the UAE

Amir is the procurement manager for a large construction firm in the UAE. He needed to address high labor costs and significant rebar material waste.

- The Challenge: Manual straightening of $12 \text{mm}$ rebar resulted in high error and a scrap rate of $7\%$.

- The Solution: Amir purchased a YG roller-type rebar straightener with a high wire feeding speed of $80 \text{m/min}$.

- The Outcome: Rebar waste was reduced to $2\%$, resulting in massive material savings. The high-wire feeding speed allowed them to deliver the first project phase $15$ days ahead of schedule, justifying the rebar straightening machine price.

Buying Guide: $3$ Questions to Ask Before Comparing Rebar Straightening Machine Price

Is it $\phi 12 \text{mm}$ or $\phi 16 \text{mm}$? This directly dictates motor power and price.

Prefabrication needs $\pm 1 \text{mm/m}$; general sites might accept $\pm 3 \text{mm/m}$.

Automation increases the initial rebar straightening machine price but drastically cuts labor costs.

Get Your Custom Rebar Straightener Machine Quote

The rebar straightening machine price represents your investment in efficiency and precision. YG Machinery guarantees transparent total cost of ownership and exceptional lifetime reliability. We offer custom solutions that meet your maximum diameter and wire feeding speed requirements.

Contact YG Machinery today for a custom rebar straightener machine quote based on your project needs and required straightening precision!