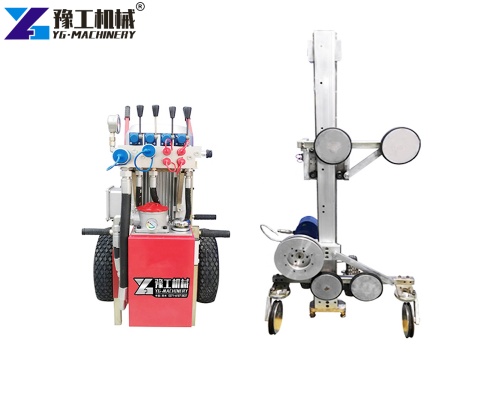

In concrete demolition and heavy-structure removal, diamond wire saw cutting provides a fast, safe, and precise method. Many contractors want to know why it is efficient and whether it fits complex jobs. YG Machinery offers diamond wire saw systems designed for thick and reinforced concrete, helping users handle demanding projects with confidence.

Diamond Wire Saw Cutting Parameter:

| Diamond Wire Saw Parameters | Hydraulic Pump Station Parameters | ||

| Wire drive mode | hydraulic | Rated output power | 22/25kw |

| Mode type | HM-40/80 | Working voltage | 380v50Hz |

| Minimum input power | 25/33HP | Hydraulic pump station | gear pump |

| Output shaft speed | 350/940/1300r/min | Motor working flow | 40-100L/min |

| Maximum wire length | 18m | Working pressure | 15-20Mpa |

| Enter method | fully hydraulic | Oil tank volume | 17L |

| Cutting machine weight | 64kg | Weight | 98kg |

| Motor weight | 14kg | Dimension(mm) | 650*550*1150 |

Deep Diamond Wire Saw Cutting Analysis and Technical Advantages

How diamond wire saw works

Diamond wire saw uses hydraulic power to drive a steel wire loop at high speed. Diamond beads generate constant cutting force and remove reinforced concrete, large blocks, and irregular shapes. The cutting process is stable and avoids vibration damage.

Technical features

- Stable hydraulic drive

- Long-lasting diamond beads

- Automatic tension system

- Works well with a hydraulic wall saw

Key advantages

YG diamond wire saw cutting offers:

- Reliable operation in narrow, wet, or underwater spaces

- High cutting speed

- Low dust and low noise

- Suitable for bridges, piers, ports, and underwater piles

- No impact on surrounding structures

Diamond Wire Saw Cutting Q&A

It usually cuts over 1 meter in thickness.

Yes, it is designed for wet and underwater jobs.

No. It is vibration-free and impact-free.

Most models cost between 8,000 and 15,000 USD.

Diamond Wire Saw Cutting Applications and Case Study

Industry applications

Diamond wire saw cutting is used for:

- Bridge demolition

- Pier and port upgrades

- Underwater pile cutting

- Urban building modification

- Tunnels and subway projects

- Industrial structure removal

It also works with concrete wire saw and wire saw cutting machine to improve performance.

Case study: John from the United States

John managed a port renovation project and needed to cut several underwater piles, every 2 meters in diameter.

Results:

- Cutting time reduced by 40%

- Clean cuts without structural damage

- Stable long-time operation

John said: “YG equipment made the project smoother and faster.”

Choosing the Right Wire Saw Cutting Machine

Key selection points:

- Hydraulic power

- Wire diameter

- Cutting depth

- Job environment

YG engineers help pick the right model.

Maintenance and cost

Costs include:

- Wire wear

- Hydraulic oil maintenance

- Wheel care

Correct tension and speed extend wire life by 30%.

YG Machinery Strength and Trust

Service support

- Project consulting

- Customized solutions

- Full spare parts supply

- 24/7 support

- Remote operation training

Customer testimonial

“YG wire saw machine is stable and reliable.” — David from Malaysia

Contact YG Machinery now for your project needs.

✔ Free quotation

✔ Tailored cutting plan

✔ Technical support