Demand for household and commercial tissue products keeps rising worldwide. A reliable tissue paper production machine helps factories increase output while keeping energy and labor costs low. Buyers want a machine that runs smoothly, saves power, and is easy to maintain.

Technical Parameter Of Tissue Making Machine:

| Model | YG1575 |

| Applicable Raw Paper | 2-3 plies 14~23gsm, Wood pulp paper |

| Raw Paper Width | Max 2100mm |

| Raw Paper Dia | Max2200mm |

| Finished Size | Φ60~130 mm |

| Finished Core Dia | Φ35mm-Φ50mm |

| Raw Paper Core Dia | 3″(76.2 mm) |

| Perforation | Spiral perforating knife, Chain wheel positioning |

| Production Speed | 200 m/min |

| Parameter Design | LCD Touch Screen |

| Control | PLC |

| Paper Feeding | 3 Unwinding stands, controlled by pneumatic |

| Air Pressure | 0.5 MPs |

| Power | 380V,50hz |

| Packaging | Wooden box |

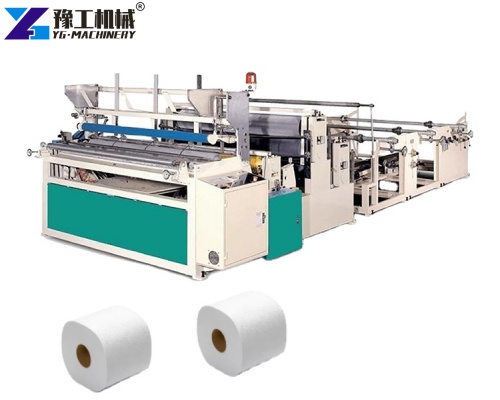

Product Overview: Understanding the Tissue Paper Production Machine

What a Tissue Paper Production Machine Does

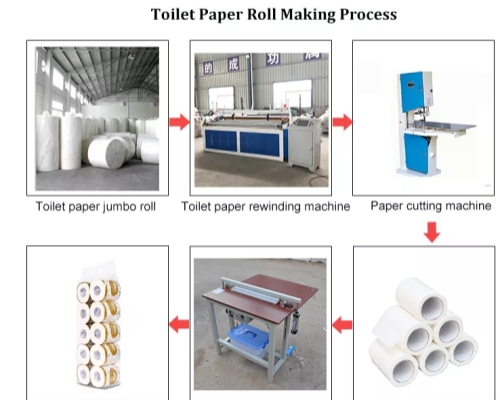

A tissue making machine transforms pulp or jumbo rolls into toilet rolls, facial tissue, or napkins.

Typical steps: embossing, rewinding, cutting, and packaging.

Technical Advantages of a Modern Tissue Paper Production Machine

- Automated tension control for stable rolls

- Energy-saving systems to reduce power costs

- High-speed rewinding improves daily output

Related equipment includes toilet paper production machine, tissue napkin making machine, and coffee cup manufacturing machine for expanded production.

Tissue Paper Making Machine FAQ

5 to 30 tons depending on the model.

No. Regular lubrication and cleaning are enough.

We can provide the raw materials, but we recommend that you purchase them locally to save on shipping costs.

Applications and Case Insights for Tissue Paper Production Machine

Where the Tissue Making Machine Is Used

- Home toilet roll plants

- Commercial jumbo roll suppliers

- Medical tissue factories

- Retail facial tissue plants

- Food-service napkin production

Buyers often search toilet paper making machine for sale or tissue paper making machine for sale when expanding capacity.

Case Study: Kim from Zimbabwe

Karim used an outdated line with high power use and poor roll stability.

After upgrading to our tissue making machine, and with our remote guidance:

- Output increased by 40%

- Energy use dropped by 20%

- Product quality stabilized

He now supplies local retailers with confidence.

How to Choose the Right Capacity of a Tissue Paper Production Machine

This is the top buyer question.

Simple rules:

- Small plants: 3–5 tons/day

- Medium plants: 6–10 tons/day

- Large plants: 10+ tons/day

Choosing the right size avoids wasted investment. We provide free capacity planning and layout support.

How to Improve Production Stability with a Tissue Paper Production Machine

To keep product quality consistent:

- Use servo control for rewinding

- Calibrate pressure rollers regularly

- Keep cutting blades sharp

- Train operators on best practices

We provide remote training to help keep long-term stability.

YG Machinery Strength and Long-Term Support

We offer:

- Pre-sales consultation

- Customised machine configurations

- Factory layout solutions

- Remote installation and operation guidance

- Long-term technical support

- Spare parts supply

Testimonial:

Robert from the USA said:

“The machine performs well. Remote support was clear and helpful. Our output increased significantly.”

If you want a stable and profitable tissue making machine, we are ready to help.

Get your:

- Free quotation

- ROI analysis

- Layout plan

📩 Contact us today and start your profitable tissue production line!